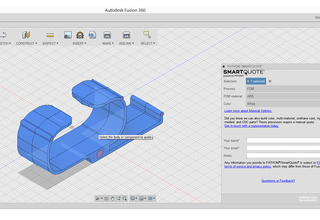

Unsuccessful change of model’s dimensions Using parameters But with complex models, you might find it nearly impossible to fix all the errors. Again, this might be fairly painless with very simple models. You will most likely have to go through the individual design steps one by one and re-write the value everywhere. if you decrease the height from 140 mm to 120 mm, but later on you do a full height chamfer, it’s still set to chamfer the old value of 140 mm, which is invalid. If you, for example, change the height of the pot in the very first design step, it will most likely create errors in the following operations. This sounds easy, but even this shape-wise relatively simple model has 18 sketches and dozens of steps in the Design history timeline. The second option is editing the dimensions manually in Fusion360. There is only so much you can do with simple scaling, What if the pot has a bigger difference between the top and bottom diameter? Scaling is not flexible enough for such a case. So at some point, parts of the model will be either too small to be printable, or if you scale it up, unnecessarily thick and tolerances too loose. Because you’ll also be scaling all tolerances, the wall thickness. This will work if the size difference is fairly small. Your first option is to simply re-scale the exported STL in the slicer. So how can we change the size in this case?ģ different self-watering plant pot inserts generated from the same Fusion360 design Scaling the model (STL) in the slicer Example 1 – Self-watering flower pot insertįirst, we’ve modeled this without the use of parameters, just like you’re probably used to modeling.

Let’s take a look at two examples and actually try to modify them to fit a different sized object. It’s really cool and if you’re not using this feature, you’re missing out a lot! If you then, later on, want to resize your model, instead of painfully changing the dimensions everywhere manually, you can simply open the parameters window, change the values here and see the model updating in real-time. For example, you can define that an edge should be “ thickness*2” long. And you can even do basic math with them. You can then use these variables whenever you’re defining dimensions. If you have experience with any kind of programming, these are basically variables. In short, if you go to Modify – Change parameters, you can define dimensions and name them. This is where parametric modeling excels. Ideally, you’d like to be able to quickly resize it to whatever size your pot is. Or a self-watering insert for a flower pot. You don’t want to re-draw it from scratch every time you buy a slightly different one.

Say, a wall-mounted holder for an aluminum LED profile. And sometimes you might even want the part to fit various different sizes or types of objects. But that’s very often not the case, right? Mechanical parts usually need to fit perfectly with other parts.

0 kommentar(er)

0 kommentar(er)